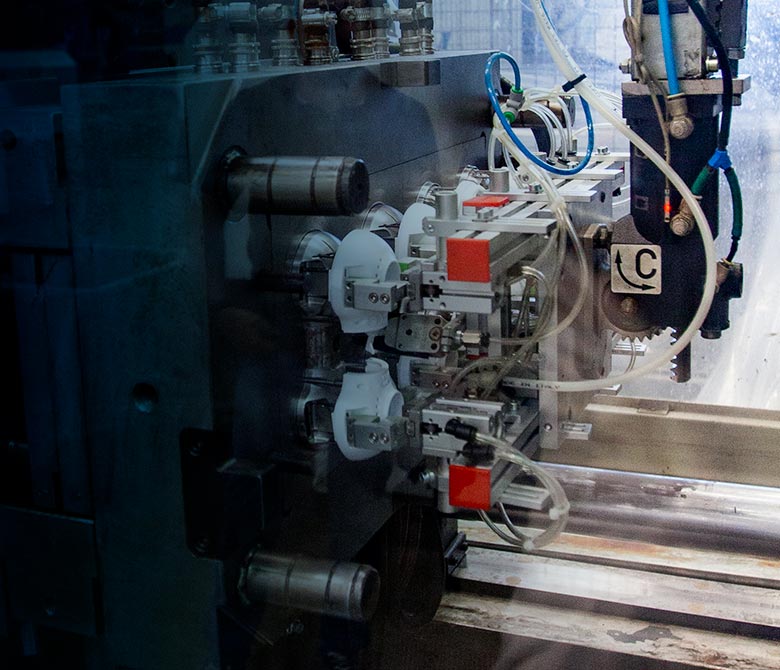

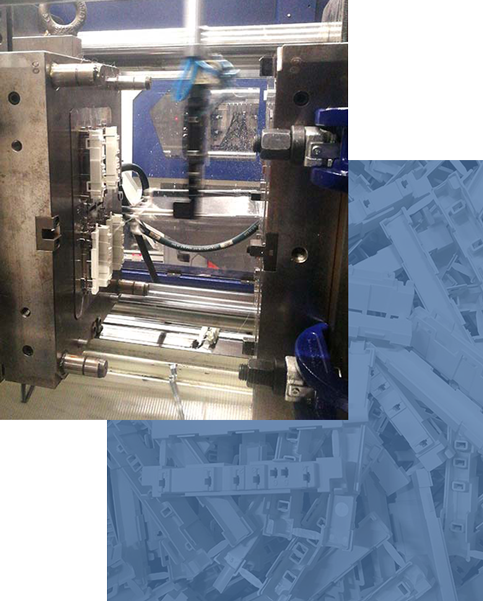

Injection molding

Plastic material injection molding consists of injecting liquid form plastic polymer into the mold. The item will then be cooled and, once solidified, extracted from the mold. MSM STAMPI has a modern thermoplastic polymer injection molding department. The warehouse supervisor manages loading and unloading. A technician is responsible for the mold testing and validation process while an expert operator carries out the programming. Lastly, a quality unit deals with quality assurance and process quality.

Small press from 0.1 to 14 gr

Traditional presses from 50 to 250 tons

One-component presses

Plastic injection molding materials

The materials supplied by MSM STAMPI are all top quality and certified, as are the masters and additives. Some of the materials we deal with are: ABS, PA6, PA6.6, PA6 + GF, PA12, PC, PC / ABS, PE, PMMA, POM, PP, PPS, PPSU, TPU, TPE, PPA, SEBS.