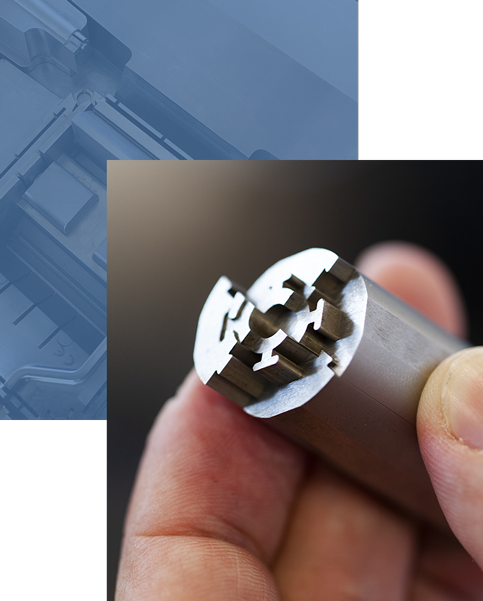

Production of molds for plastic materials and metals

MSM STAMPI specializes in the construction of small, medium and large injection molds, implementing a complete series of machinery: CNC centers such as DMG, MAKINO and HWACHEON, Charmilles and Fanuc wire erosion, Charmille and Ona dip erosion, all equipped with Cam stations.

Modern and fully equipped internal workshop

Just-in-time checking of all construction phases

From pilot molds to multi-cavity molds

Dimensions varying from Babyplast to 1200 x 800 mm

3.500 m²

TOTAL

OPERATING AREA

3 workstations

WITH 3D

VISI CAD DESIGN

17 machines

FOR MOLD

CONSTRUCTION

13 operators

SPECIALIZED IN

MOLD CONSTRUCTION

MSM STAMPI

Plastic material and metal mold design

Our technical office has three 3D-VISI-CAD stations all directly connected to the workshop: we are therefore able to offer you our support from the very early stages of your project. Our wide range of machinery and solid know-how also allow us to produce a large variety of components in-house.

Co-design and product engineering

Study and construction of the mold project

Choice of the most suitable material for molding

Mold filling simulation